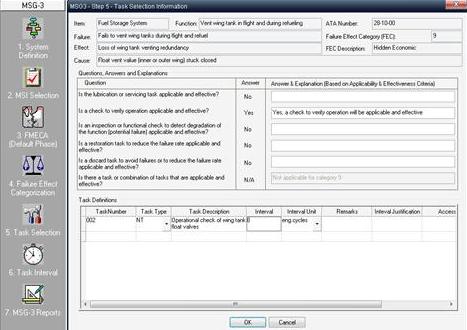

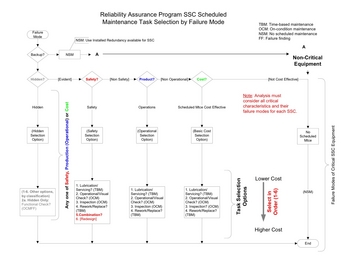

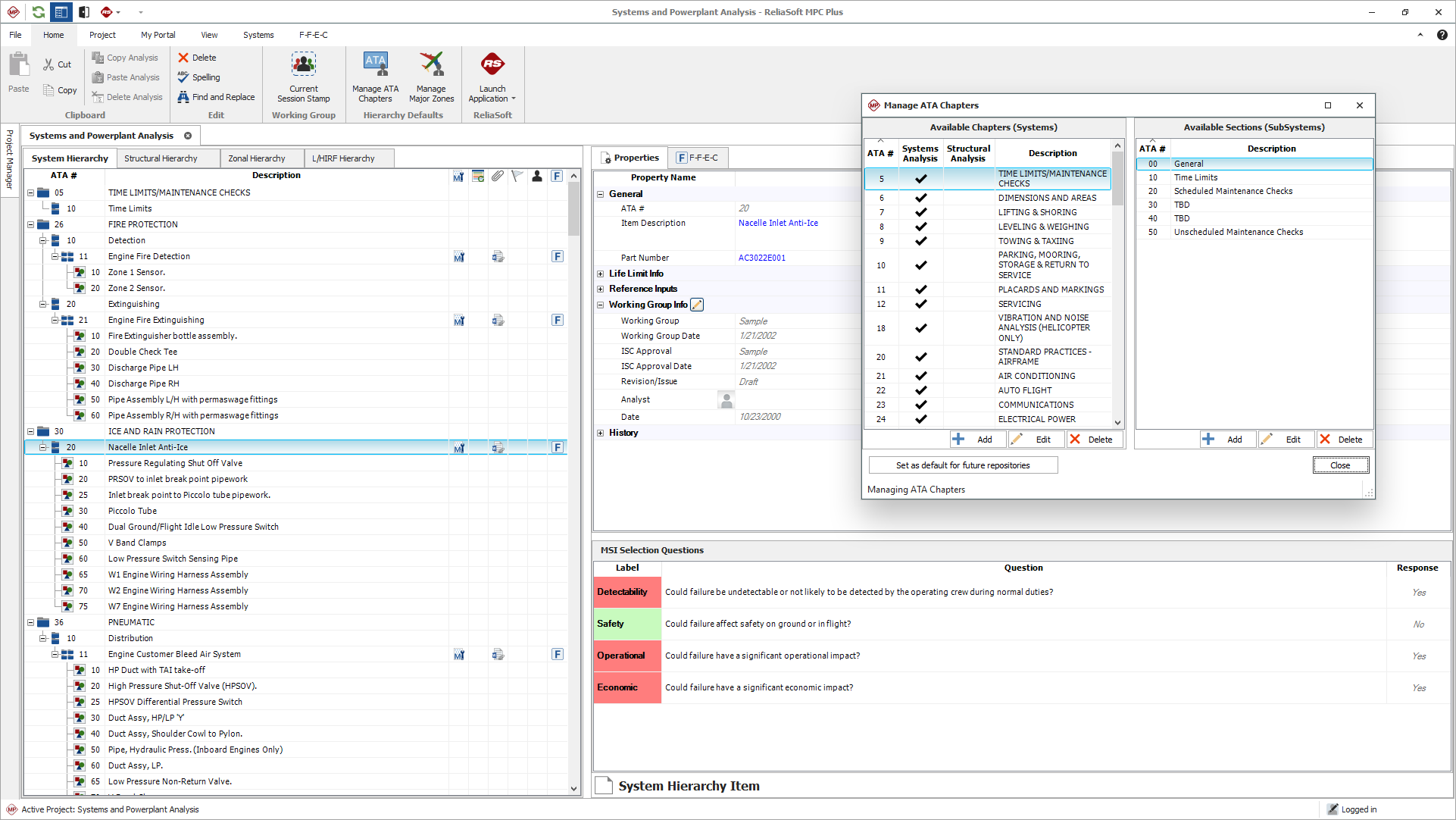

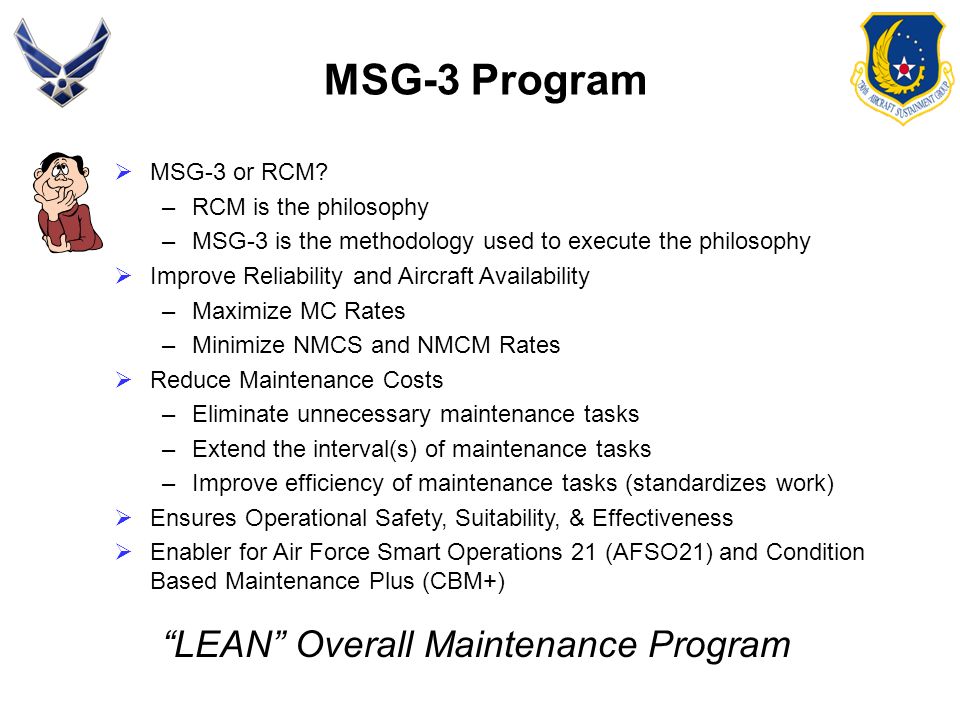

MSG3 is a Topdown process, which enables a step by step systematic analysis MSG3 delivers lower maintenance costs with typical savings ranging from 15% to 25% for the same aircraft type onMSG3 is listed in the World's largest and most authoritative dictionary database of abbreviations and acronyms MSG3 is listed in the World's largest and most authoritative dictionary database of abbreviations and acronymsThe MSG3 module is integrated with RAM Commander Reliability and FMECA modules It divides the procedure into 7 steps including system definition, maintenance significant items selection, failure effect categorization, task selection and development and report generation The MSG3 module guides the user through the decisionmaking process

What S In An Msg 3 Inspection Sofema Aviation Servicessofema Aviation Services

Msg 3d seating chart concert

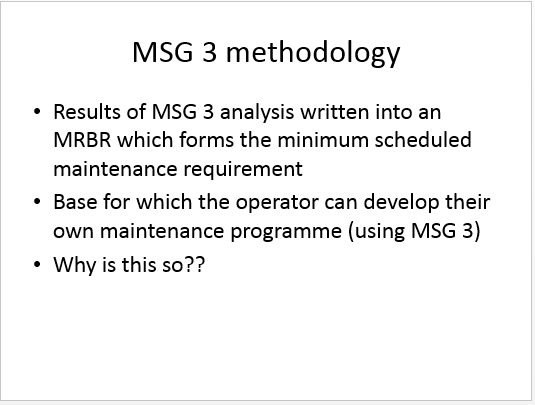

Msg 3d seating chart concert-An inspection is A GENERAL VISUAL INSPECTION (GVI)MSG3 is now the preferred method used for developing the scheduled maintenance tasks and intervals which will be acceptable to Regulatory authorities, Operators, and Manufacturers This course is intended to support a deeper understanding of the Role of the Maintenance Process The role of MSG3 the obligations of the THC STCH and the Operator To promote an effective

Ata Msg 3 Maintenance Process Logic Breakdown 15 Download Scientific Diagram

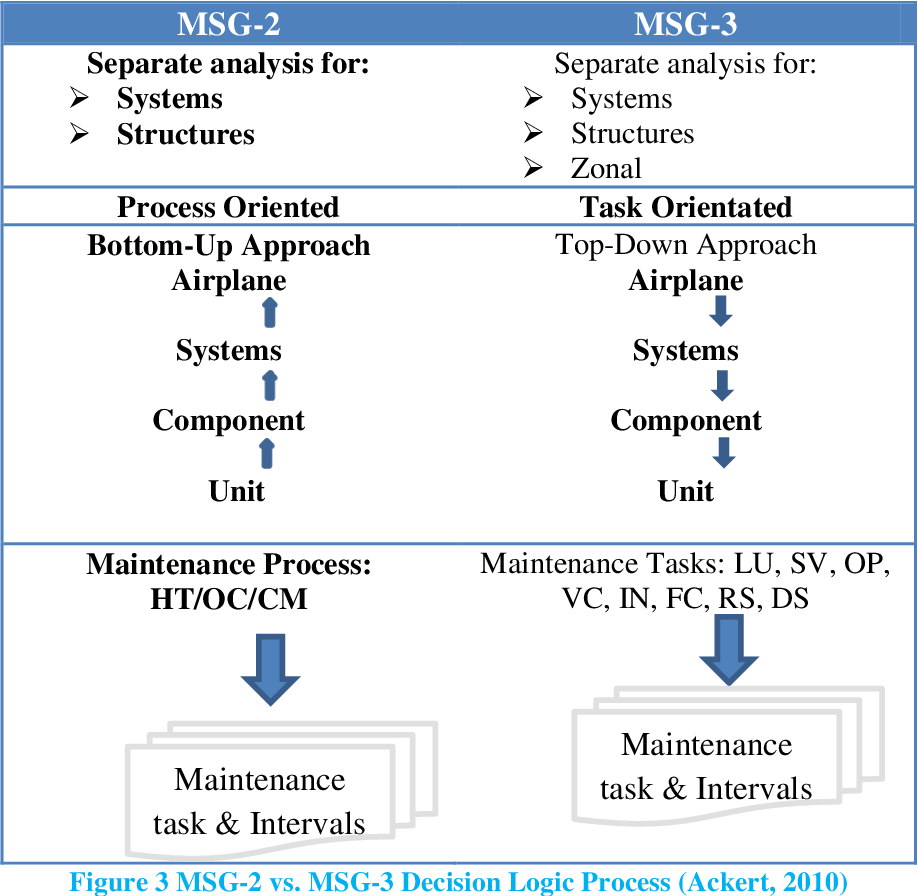

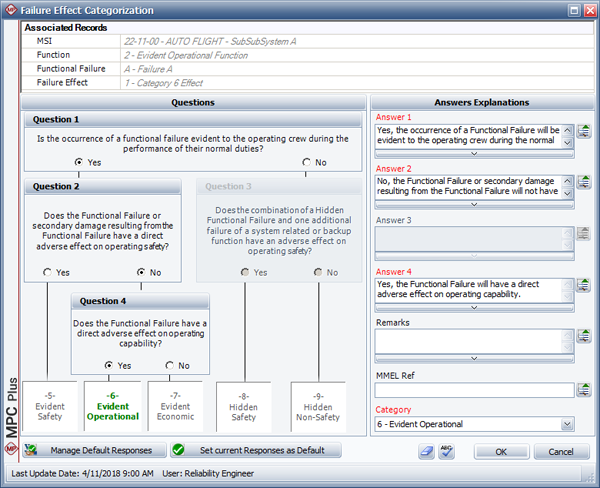

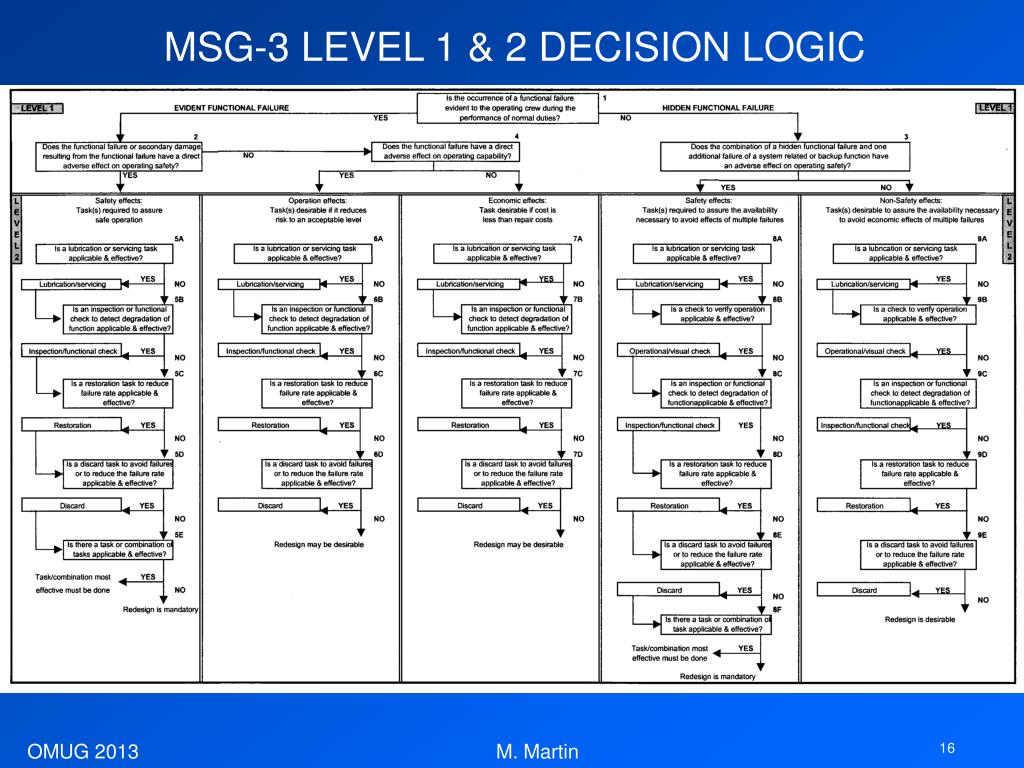

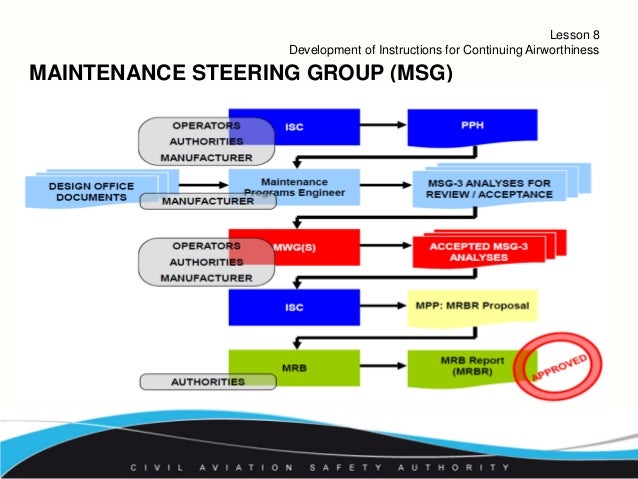

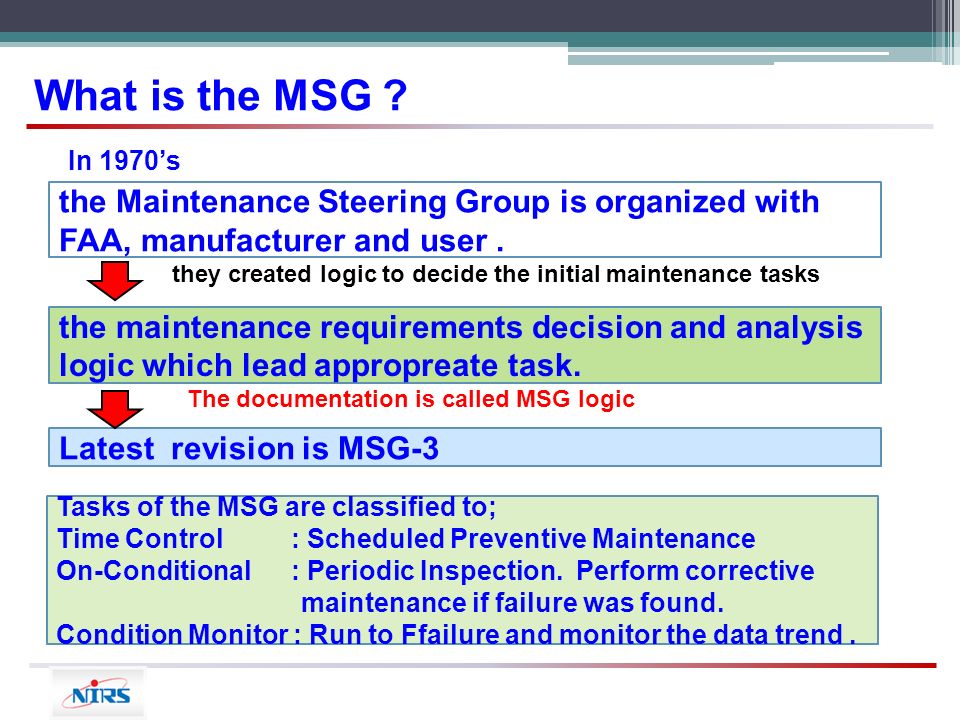

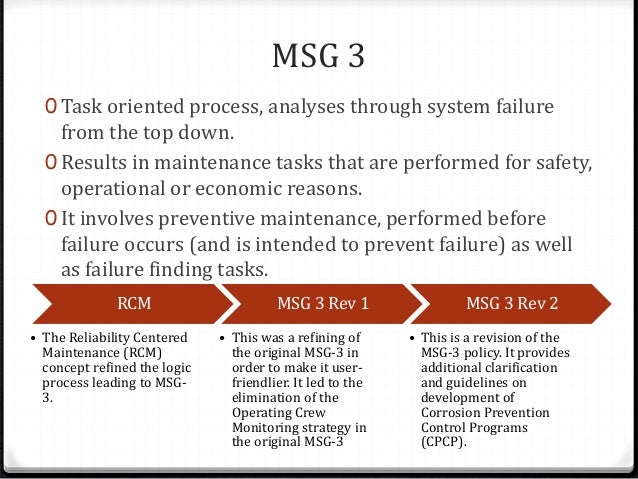

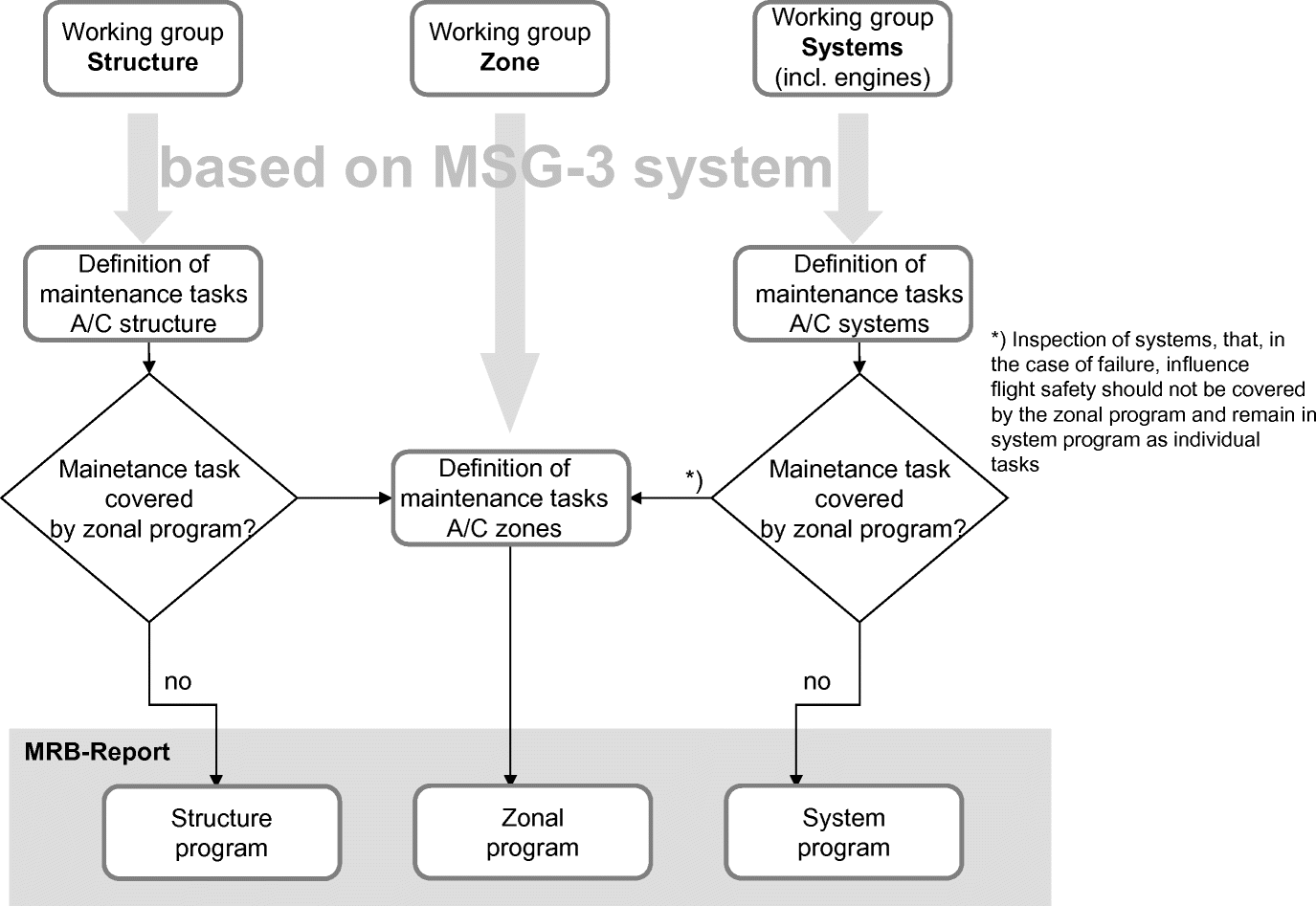

MSG/3REPORT 21 MSG/3 Report on Agenda Item 2 REPORT ON AGENDA ITEM 2 FOLLOWUP ON THE OUTCOME OF MIDANPIRG/13 MEETING 21 The meeting was apprised of the outcome of the Thirteenth meeting of the Middle East Air Navigation Planning and Implementation Regional Group (MIDANPIRG/13) held in Abu Dhabi, UAE, 22 26 April 12MSG3 is a structured process for identifying Safety Significant Items (SSI), defining for each SSI the failure modes and effects (FMEA) A decision tree is then applied to decide the maintenance strategy for each SSI Leading aircraft manufacturers use BQR's MSG3 software Benefits Quick and accurate analysis Data is organized and maintained in one software rather than many excelThis new methodology was the basis for MSG3, the current industry standard This methodology has a taskoriented approach to maintenance that analyzes system failure modes from a system level, or top down Maintenance tasks are performed for safety, operational, or economic reasons They involve both preventive maintenance and failure finding tasks Revisions to the MSG3

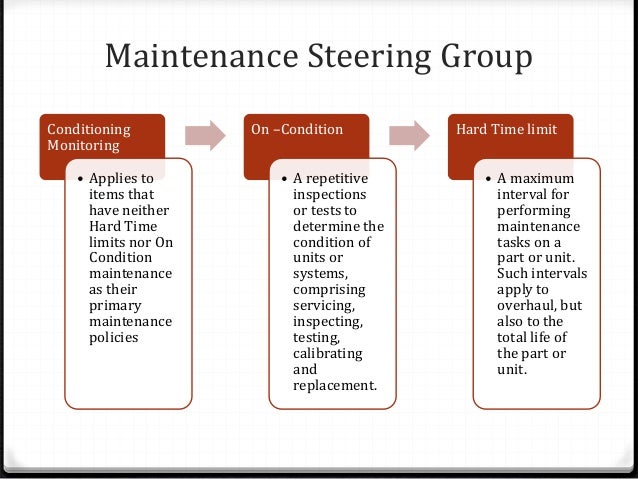

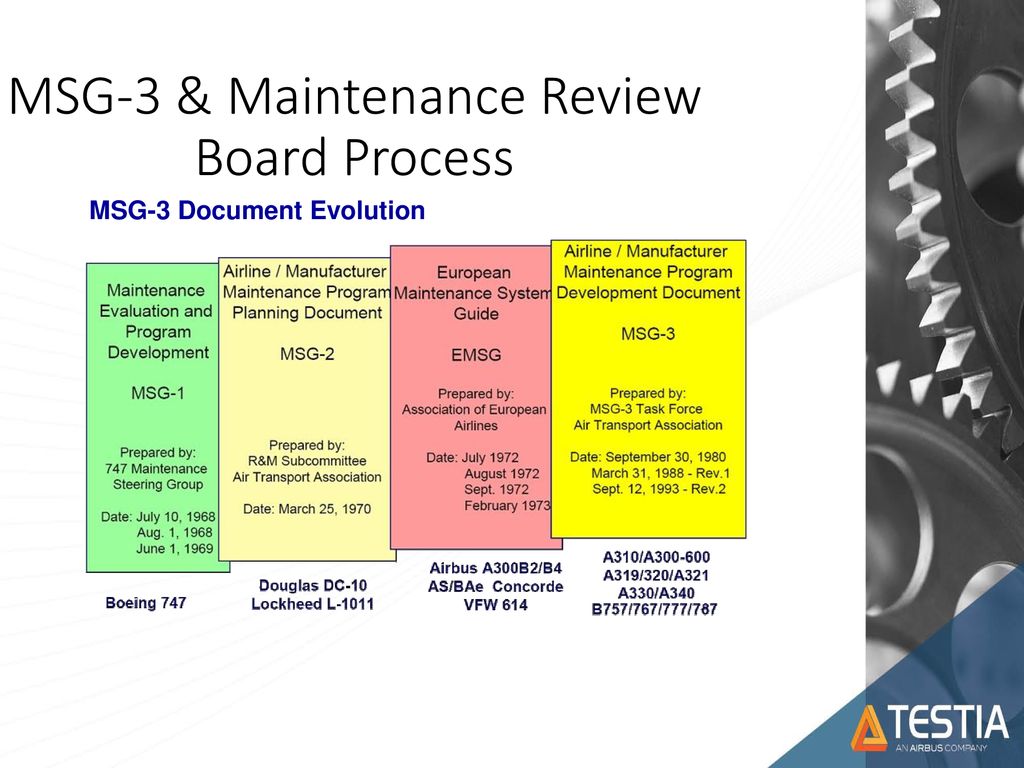

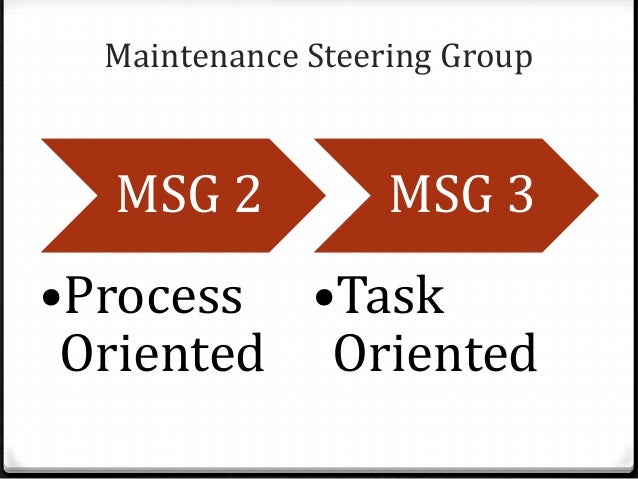

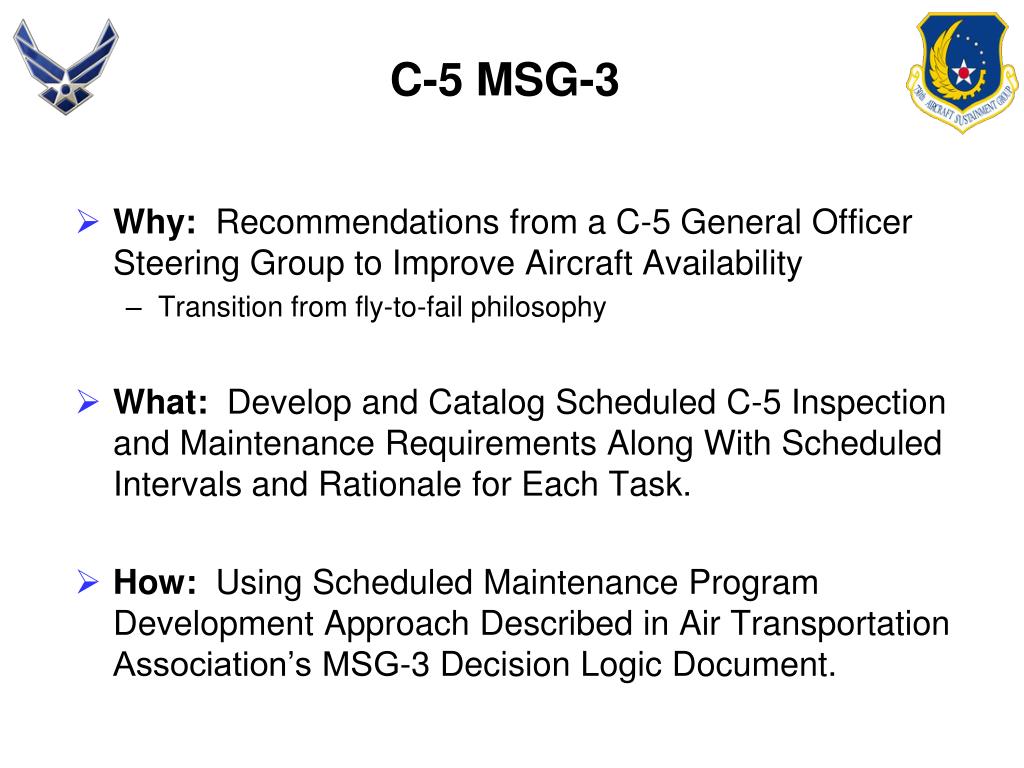

Maintenance tasks in the MSG3 model are performed for safety, operational, or economic reasons History and Evolution of MSG3 MSG3 can trace its roots back to 1968 when the Air Transport Association (ATA) released the document "Maintenance Evaluation and Program Development" which became known in the industry as MSG1 An Introduction to MSG3 In the early days of aviation, maintenance requirements were determined by a few experienced mechanics with assistance from the manufacturer As the aircraft became more complex through technological advancements, it was recognized that a more sophisticated method of developing maintenance programs was neededMSG3 is now the preferred method used for developing the scheduled maintenance tasks and intervals which will be acceptable to Regulatory authorities, Operators, and Manufacturers This course is intended to support a deeper understanding of the Role of the Maintenance Process The role of MSG3 the obligations of the THC STCH and the Operator To promote an effective

Translations in context of "MSG3" in FrenchEnglish from Reverso Context Plutôt que d'identifier des procédés, le MSG3 identifie des tâches de maintenance24 Msg3 jobs available on Indeedcom Apply to System Engineer, Aircraft Structural Repairer, Senior Safety Engineer and more!Step (F) MDPDCCH for Msg 4;

Msg 3 Europe S Latest Weather Satellite Delivers First Image Eumetsat

Earth Observing Geostationary Satellite Platforms A Msg 3 At 0 Download Scientific Diagram

MSG3 is a Topdown process, which enables a step by step systematic analysis MSG3 delivers lower maintenance costs with typical savings ranging from 15% to 25% for the same aircraft type on conversion from MSG3 to MSG3 MSG3 typically delivers a substantial cost reduction in hard time component removal and replacementThe MSG3 guidelines have been developed to provide the aircraft industry with a logical framework for creating initial scheduled maintenance plans that will be acceptable to regulatory authorities, operators and manufacturers This article provides a general overview of MSG3 and discusses the systems and powerplant portion of the analysis inExamples NFL, NASA, PSP, HIPAA,random Word(s) in meaning chat "global warming" Postal

Ulrica Pen In Aviation Aircraft Maintenance What Is Msg

The Role Of Msg 3 In Reducing The Cost Of Aircraft Maintenancesofema Aviation Services

MSG3 is the third in a series of four satellites introduced in 02 These spinstabilised satellites carry the primary Spinning Enhanced Visible and Infrared Imager, or SEVIRI The prime contractor for the MSG satellites is Thales Alenia Space, with the SEVIRI instrument built by Astrium SEVIRI delivers enhanced weather coverage over Europe and Africa in order to improvePresentazione del software SYS_MSG per la ricezione e gestione delle immagini da Meteosat Seconda Generazione 3° parte di 3MSG3 is a structured process for identifying Safety Significant Items (SSI), defining for each SSI the failure modes and effects (FMEA) A decision tree is then applied to decide the maintenance strategy for each SSI Leading aircraft manufacturers use BQR's MSG3 software Benefits Quick and accurate analysis Data is organized and maintained in one software rather than many excel

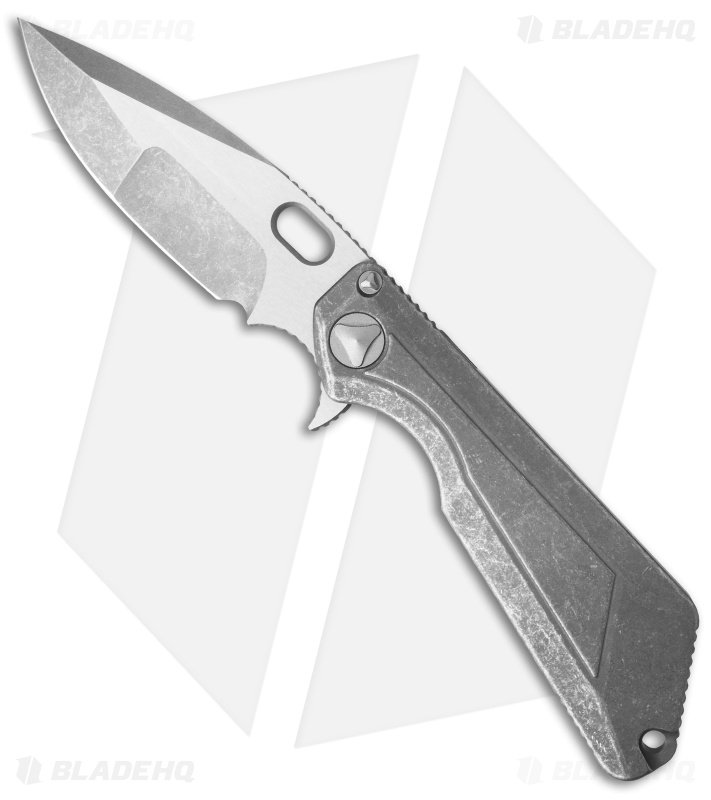

Microtech Knives Custom Titanium Msg Iii Spear Point Flipper Knife 3 5in Apocalyptic Plain M390 Mtc 0098 Hollow Grind

Dynamic Resource Allocation Of Random Access For Mtc Devices Lee 17 Etri Journal Wiley Online Library

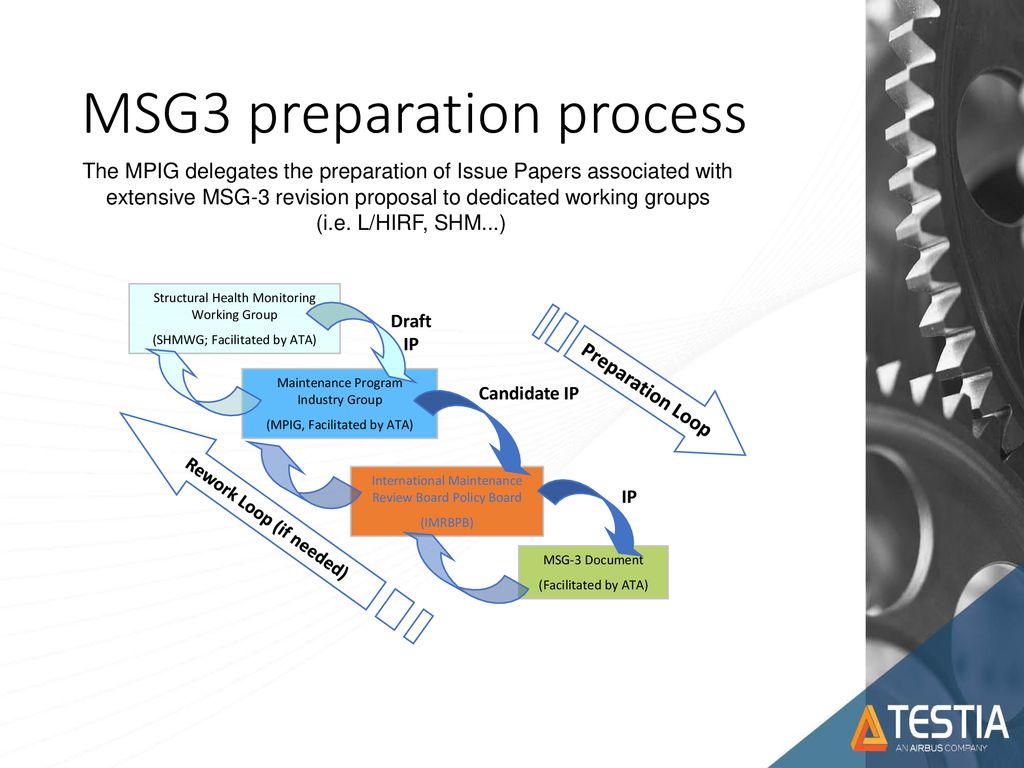

Effective For the time being, MSG3 only takes into account Scheduled SHM (SSHM) Dedicated analysis procedures need to be developed and approved/accepted at the level of the PPH for such technology 2 Inspection Thresholds The inspection threshold for each SSI inspection task is a function of the source of damage as follows aLooking for online definition of MSG3 or what MSG3 stands for?MSG3 is the third satellite of a planned series of four successive satellites These satellites are part of the meteosat program and will be primarily used for so called "nowcasting" purposes 10h01'22" ITW Tim hewison, Eumetsat, Meteorologist (shot at Eumetsat, Darmstadt DE ) So nowcasting is forecasting the weather in the next few hours To do that we rely very heavily

1

Sharetechnote

SUPPORT and CONDUCT MSG3 analysis to achieve optimal balance on aircraft's maintenance/failures costs and availability & safety improvements Course Agenda For more details on course agenda, please click here Who Should Attend The course is designed to meet the needs of aviation personnel who require a comprehensive understanding of MSG3 The courseIn short, Legacy LTE RACH and LTE BL/CE RACH are same in terms of general big picture and overal protocol sequence as follows The main purpose of RACH process is to achieve Uplink synchronization and obtain the grant for initial attach; The ATA MSG3 publication outlines a decisionlogic process for determining initial scheduled maintenance requirements for new aircraft and/or power plants This document presents a means for developing maintenance tasks and intervals acceptable to regulatory authorities, operators and manufacturers Document History MSG3 MSG3

Msg 3 Module For Scheduled Maintenance

Anthony Marfione Prototype Integral Msg 3 Hp Blade Free Shipping Empire Outfitters

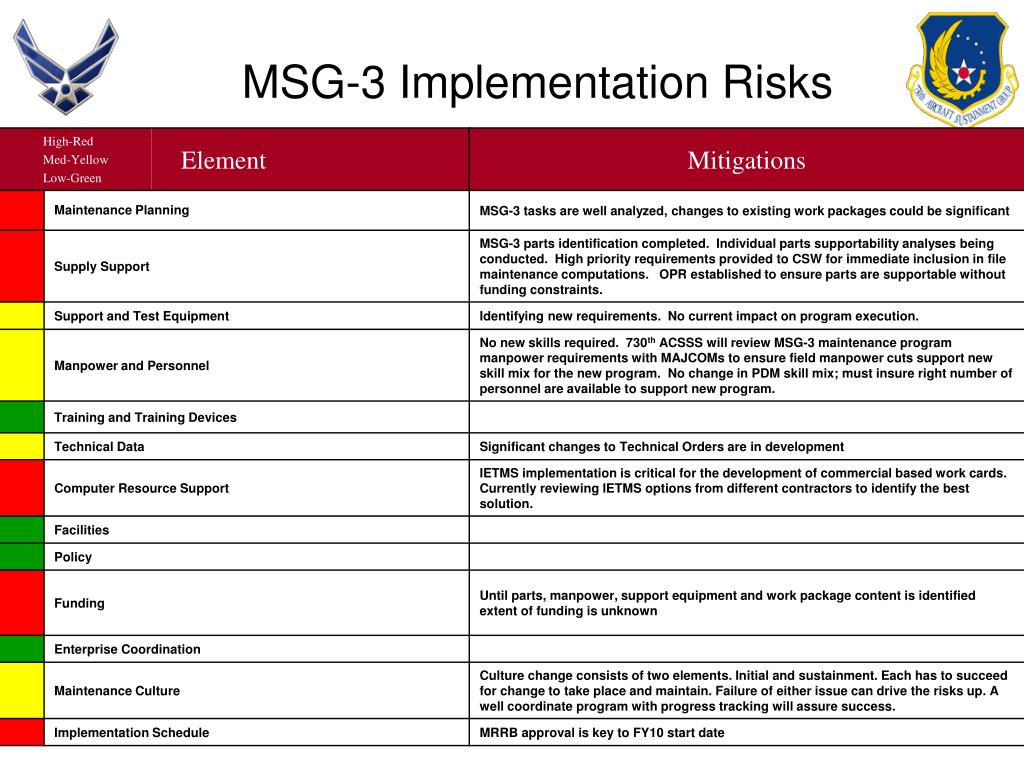

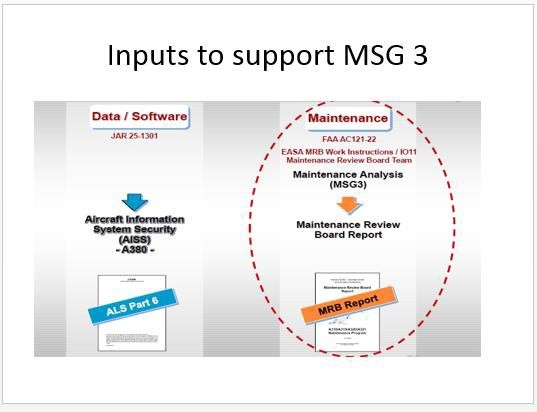

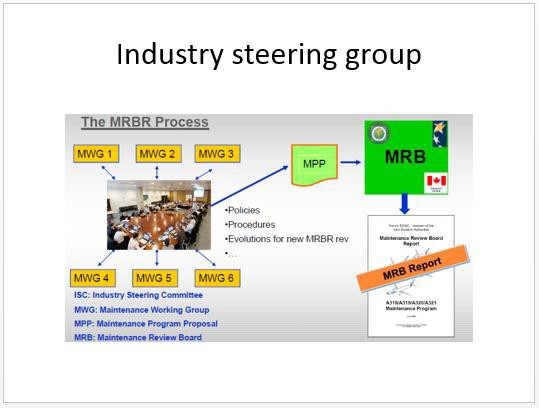

During the MSG3 analysis, a team consisting of the OEM, operators and the regulatory authorities analyzed every aircraft system, including airframe structure and wiring installation, to determine the failure modes, their criticality, the ease of their detection, the level of inspection required and the ideal recurrence of inspection This is where the varied experience of the teamChristian Fellowship ChurchPastor Daniel ParkerMeteosat10 (MSG3) 05 July 12 Availability lifetime is until 30 Meteosat11 (MSG4) 15 July 15 Availability lifetime is until 33 The contract for the second generation was awarded to Aérospatiale in its Cannes Mandelieu Space Centre (now Thales Alenia Space), with main subcontractors as Matra, Messerschmitt, Alenia Meteosat Second Generation was designed in

Keeping The C 5 Fleet In Check U S Air Force Article Display

Reuter Electronic Msg 3 1 Printing Machine Parts

MSG3 main missions Imaging mission one Image every 15 minutes 12 spectral channels pixel size 25x25 km (1 visible & 10 infrared channels, full earth disc) pixel size 10x10 km (1 visible channel, 50% of earth disc, selectable footprint) MSG3 missions (1) Slide 7 ESA UNCLASSIFIED – For Official Use MSG3 secondary missions GERB (Global Earth Radiation Budget) Measurement inSAE JA1011, Evaluation Criteria for ReliabilityCentered Maintenance (RCM) Processes, Society ofThe MSG3 module is integrated with RAM Commander Reliability and FMECA modules It divides the procedure into 7 steps including system definition, maintenance significant items selection, failure effect categorization, task selection and development and report generation It brings user through the decisionmaking process using interactive

What Is The Difference Between Msg1 Msg2 And Msg3 Aviation Nuggets

Msg 3 Se The Patriot Carbine Xm16e1 By Theqroks On Deviantart

Overall protocol sequence of the processMSG3 Operator/Manufacturer Scheduled Maintenance Development (Vol 1 – Fixed Wing Aircraft and Vol 2 – Rotorcraft) Revision 181, Airlines for America, 18;(Your IP Address 2) Homeserve Furniture Repairs Copyright 21 © All Rights Reserved

Msg 3 Satellite Ready To Continue Weather Monitoring Service

Intelligent Maintenance Program Ppt Video Online Download

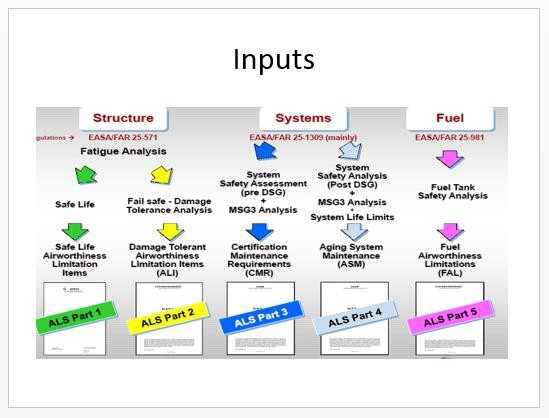

ReliaSoft MPC is an MSG3 compliant maintenance program creator for the aircraft/aerospace industry The software has been designed to assist MSG3 working groups to perform Systems and Powerplant Analysis, Structural Analysis and/or ZonalL/HIRF Analysis in accordance with the MSG3 Operator/Manufacturer Scheduled Maintenance Development guidelinesMSG3 recognized the new damage tolerance rules and the supplemental inspection programs, and provided a method by which their intent could be adapted to the Maintenance Review Board (MRB) process instead of relying on type data certificate restraints Concepts such as multiple failures, effect of failure on adjacent structure, crack growth from detectable to critical length, and MSG3–A Method For Maintenance Program Planning When a new aircraft is introduced into airline service, it must have a maintenance and inspection program approved by the Federal Aviation Administration (FAA) The "Airline/Manufacturer Maintenance Program Planning Document," commonly known as MSG3, is a method used (by the

Anthony Marfione Prototype Integral Msg 3 Hp Blade Free Shipping Empire Outfitters

Msg 3 Sohar Service

MSG3 Analysis FOR MSI Fuel Storage System Effectivity Xwing Fighter Spaceship Revision 3 Date 08/27/09 Company ALD Department Reliability&Safety SCHEDULED MAINTENANCE DEVELOPMENT DATA MSI Xwing Fighter Spaceship Fuel Storage System Prepared by Date Workgroup Approval Revision Update Date Page ALD 08/Level 3, Revision 2 (MSG3 Rev 2) standards are the same as those used to develop scheduled maintenance requirements for the 777, /700/800/900, and 717 MSG3 Rev 2 methodology also was used to update maintenance programs for the MD80, DC9, DC10, and DC8 during the late 1990s Updated maintenance programs for the 727 and 7370/300/Maintenance Steering Group 3rd Task Force (MSG3), Original Revision () In 1980, the combined efforts of the FAA, ATA tasking/interval requirements, US and European aircraft and engine manufacturers, and US and foreign airlines generated new decision logic and analysis procedures contained in a new document called MSG3 8/27/12 AC C AC 121

Msg 3 Arizona Custom Knives

Aircraft Maintenance Cost Modelling Considering The Influence Of Design Parameters Semantic Scholar

MSG3, The Intelligent Maintenance Sign up for Aviation Pros eNewsletters SIGN UP Latest in Engines & Components Credit Lee Aerospace Windows Lee Aerospace Now Offers Learjet 55Step (E) Msg 3;Step (G) Msg 4 What are same ?

Woa1 Random Access Procedure Performing Method In Wireless Communication System And Apparatus Therefor Google Patents

Esa Msg 3 Solar Panel Check

ATA MSG3 SHM WG Detailed Proposal Rev 1, dated 237 Task Development (Second Level) 3 Inspection/Functional Check (All Categories) QUESTION 5B, 6B, 7B, 8C & 9C IS AN INSPECTION OR FUNCTIONAL CHECK TO DETECT DEGRADATION OF FUNCTION APPLICABLE AND EFFECTIVE?Acts 3Open menuThe MessageOpen menu 3 15 One day at three o'clock in the afternoon, Peter and John were on their way into the Temple for prayer meeting At the same time there was a man crippled from birth being carried up Every day he was set down at the Temple gate, the one named Beautiful, to beg from those going into the TempleThe MSG3 domain defines the MSG3 inspection types You can modify the inspection types to meet the requirements of your organization You select the MSG3 inspection type on task card records, master task card records, job cards, and work orders The following MSG3 inspection types are defined by default LubricationServicing (LUSV) A group of maintenance tasks that

Anthony Marfione Prototype Integral Msg 3 Hp Blade Free Shipping Empire Outfitters

Msg 3 Successfully Launched Eumetsat

(Your IP Address 1171) Homeserve Furniture Repairs Copyright 21 © All Rights ReservedCheck out our msg 3 selection for the very best in unique or custom, handmade pieces from our shopsMSG3 stands for Maintenance Steering Group3 MSG3 is defined as Maintenance Steering Group3 rarely Printer friendly Menu Search New search features Acronym Blog Free tools "AcronymFindercom Abbreviation to define Find abbreviation;

2

Aircraft Maintenance Program

Aeronovo is a Canadian aerospace company specialized in MSG3 training courses Aeronovo supports customers in the development of Maintenance Programs in accordance with MSG3 methodology, MRB process and all Regulatory related requirements Aeronovo offers customized maintenance programs resulting in significant financial profits AeronovoMSG 3 delivers a top down approach which focuses on the need to ensure either economic viability or to maintain the aircraft system, component or structure in an airworthy condition For each potential failure cause, the MSG3 guidelines provide task oriented logic to determine the appropriate scheduled maintenance tasks The resulting task oriented program consists of

From Ndt To Shm A Practical Approach Ppt Download

From Ndt To Shm A Practical Approach Ppt Download

Marfione Custom Strider Msg 3 Flipper M390 Blade Frag Titanium Chassis Apocalyptic Finish

2

Fueling Begins With Europe S Msg 3 Satellite Payload For The Next Ariane 5 Launch Arianespace

1

Benefits Of Optimizing Maintenance Intervals Pdf Free Download

Msg 3 Maintenance Steering Group

How To Use Msg 3 Image Nuclear Engineering International

Ulrica Pen In Aviation Aircraft Maintenance What Is Msg

Conditioned Based Maintenance Plus Cbm Is Your Program Ready Dayton Aerospace

Maintenance Steering Group Fatigue Concepts

Intelligent Maintenance Program Ppt Video Online Download

5g Waveform Candidate 5g Sharetechnote

Reliability Centered Maintenance And Msg3 Dmd Solutions

Esa Msg 3 Logo

Msg 3 Aircraft Inspection Considerations Sofema Aviation Servicessofema Aviation Services

Maintenance Steering Group 3 Msg 3 Ppt Video Online Download

Ata Msg 3 Maintenance Process Logic Breakdown 15 Download Scientific Diagram

Msg Vol 3 Mkultra Support Group Msg

Mpc Msg 3 Maintenance Program Creator Software Reliasoft

Creating Initial Scheduled Maintenance Plans For Aircraft Msg 3 Reliasoft

Ata Msg 3 Maintenance Process Logic Breakdown 15 Download Scientific Diagram

x1800 Motivational Msg 3 Macbook Pro Retina Hd 4k Wallpapers Images Backgrounds Photos And Pictures

What S In An Msg 3 Inspection Sofema Aviation Servicessofema Aviation Services

2

Maintenance Steering Group Fatigue Concepts

Madison Square Garden Iii Pt 1 Demolished New York New York Bob Busser

Basics Of Aircraft Maintenance Programs For Financiers Pdf Free Download

Msg3 Game

Marfione Strider Custom Msg 3 Flipper Knife Ti 3 5 Two Tone Apocalyptic Iii Blade Hq

Msg 3 Maintenance Steering Group

1

International Standard

Anthony Marfione Prototype Integral Msg 3 Hp Blade Free Shipping Empire Outfitters

Maintenance Steering Group Fatigue Concepts

Metal Gear Solid 3 Snake Eater Wikipedia

Maintenance Steering Group 3 Msg 3 Ppt Video Online Download

Creating Initial Scheduled Maintenance Plans For Aircraft Msg 3 Reliasoft

Ppt Reliability Centred Maintenance Rcm Powerpoint Presentation Free Download Id

5 Meteosat 9 Msg 2 And Meteosat 10 Msg 3 Coverage Centered At 9 5 Download Scientific Diagram

Msg 3 Msg The Warrior Lion Heart Trailer Review Out Now Youtube

Heckler Und Koch Hk Msg90 Hk Msg3 Sniper Rifle Germany Modern Firearms

2

Msg 3

Aircraft Maintenance Program

Ppt Maintenance Steering Group 3 Msg 3 Powerpoint Presentation Free Download Id 3244

Ulrica Pen In Aviation Aircraft Maintenance What Is Msg

Cmr

Msg 3 Maintenance Steering Group

2

Maintenance Steering Group Fatigue Concepts

Maintenance Steering Group Fatigue Concepts

Ulrica Pen In Aviation Aircraft Maintenance What Is Msg

Ppt Maintenance Steering Group 3 Msg 3 Powerpoint Presentation Free Download Id 3244

Msg 3 Trailer Will Surely Take You To The Next Trippy Journey Filmymantra

Coscap Sa Legal Requirement Icao Annex 6 Para

First Official Motion Poster For Msg 3 The Warrior Lion Heart Released

Anthony Marfione Prototype Integral Msg 3 Hp Blade Free Shipping Empire Outfitters

Dailyo Opinion News Analysis On Latest Breaking News India

Ata Msg 3 Ata Spec Online Store

File The Black Keys At Msg 3 22 12 Jpg Wikimedia Commons

How To Beat The End In Metal Gear Solid 3 8 Steps With Pictures

Ulrica Pen In Aviation Aircraft Maintenance What Is Msg

Ppt Maintenance Steering Group 3 Msg 3 Powerpoint Presentation Free Download Id 3244

Marfione Custom Knives Mick Strider Msg3 Integral Flipper 3 5 M390 Two Tone Apocalyptic Blade Titanium Handles Nylon Pouch Knifecenter Discontinued

The Relationship Importance Of Reliability Datasofema Aviation Services

Msg 3

Msg 3 Analysis Course Brochure And Syllabus Regional Services

Intelligent Maintenance Program Ppt Video Online Download

Aircraft Maintenance Program

2

Maintenance Management Springerlink

2

2

Maintenance Steering Group 3 Msg 3 Based Maintenance Steering Group 3 Msg 3 Based Pdf Pdf4pro

Microtech Marfione Custom Msg 3 Frag Knife Stonewashed M390 Blade Titanium Frame

5g Waveform Candidate 5g Sharetechnote

0 件のコメント:

コメントを投稿